Detailed introduction

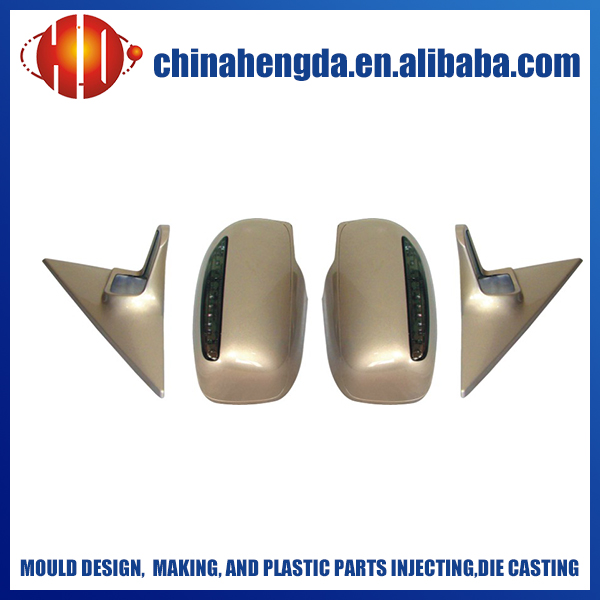

2014 rearview mirror mould making

What is Details of our products?

Features:

| Mould material | P20 steel, 718, 2738, H13, NAK80, 2344, 2343, S136, etc . |

| Runner | Cold runner. Hot runner: Yudo/DME/HASCO |

| Certificate | ISOTS16949 |

| Standard | HASCO, DME, LKM |

| Specification drawings | Pro/E, Auto CAD, Solidwork, CAXA UG, CAD/CAM/CAE. |

| Precision machining | CNC, milling machine, drilling machine, numerical lathe, all types of lathe |

| Surface finish process | polishing, sand blasting, heat treatment, painting, powder coating, anodizing, electroplating, mirror polishing . |

| Shaping mould | injection mould |

| Mould life | above 500,000SHOTS |

| Service | OEM service available, good after-sales service . |

| Lead time | 4-7 weeks, 40 days or according to the real situation . |

What is Advantages of our company ?

Our anvantages

| High quality |

Reasonable price | |

| Strict delivery time | |

| Good after-sales service | |

Profession maker for 21 years | |

Gold supplier 9th year | |

Strict quality control | |

| professional injection mould | |

| 3D design |

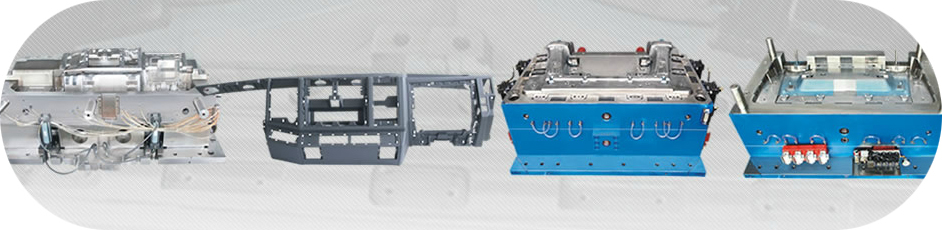

Product Photos

Plastic injection

mould, die casting mould, auto/household/parts mould.....

Our Certifications Of Honor

Company View

Project Case:

Our Exhibition

Our business partners

FAQ:

1.Q:Are you a factory or trading company?

A: We are a factory.

2.Q:Where is your factory located? How can I visit

there?

A: Our factory is located

in Taizhou City, China.You can fly to Ningbo airport

directly.All our clients, from home or abroad, are warmly welcome to

visit us!

3.Q:How can I get some samples?

A: We are honored to offer you

samples.

4.Q:How does your factory do regarding quality

control?

A:"Quality is priority.

we always attach great importance to quality controlling from the very

beginning to the very end. Our factory has gained ISOTS16949 authentication.

Why Choose us?

About us:

Established in 1992, our company can make both plastic injection and die casting mold, parts are also available.We started with manufacturing home appliance mould, and entered auto part mould industry since 2000. We have cooperated with BMW, Metagal, Hisense,Toshiba etc. We have about 220 employees, 22 sets plastic injection machines from 80-1250 Tons, 4 diecasting machines from 160-400 Tons.

Hengda has a full set of advanced technology and facilities, such CAD/CAM/MOLDfiow software, and also has a lot of experienced professiomal mould designers and technicians.

We are China Leading Moulding Manufactuer

Alibaba Assessed 10 years Gold Supplier.

Inspected by the Inspection Institution of Bureau Veritas Certification.

100% QC inspection Before Shipmeng.

Best Quality & Best Service with Competitive price.

How to Contact Us?

If you are interested in any mould, please send the details to us by email. We will quote you the best price with the superior standard mould.

We specialize in plastic injection mould / die casting mould for auto, luggage, household, office, buliding panel, etc.

If you are interested in our cooperation, please send us samples or drawing for further check.

Any mould is OK, just send us your drawing or sample, we can make it for you.

And we warmly welcome friends from all over the world to visit our factories for business.

Send your Inquiry Details in the Below, Click "Send" Now!